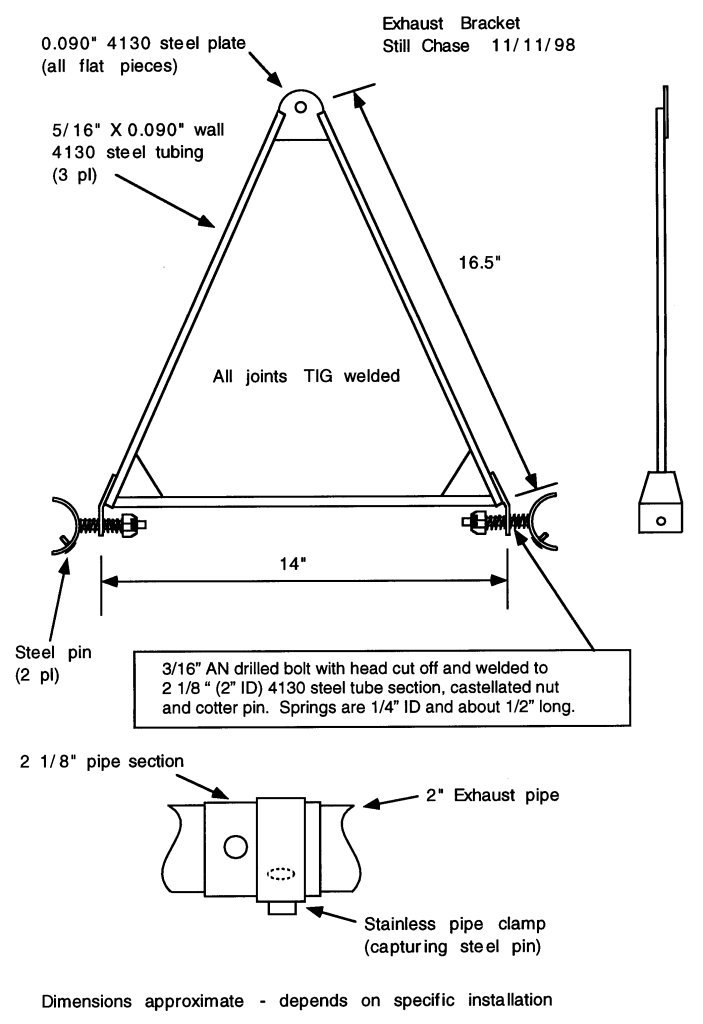

CESSNA 120/140 EXHAUST BRACKET.

Having tired of re-welding the exhaust bracket on my C140, I designed the one shown in the attached drawing. The idea was to allow limited movement of the pipe ends so that vibration, expansion/contraction would not continue to crack the welds at the clamps.

I used the original bracket as a jig to make a welding fixture to hold all the parts in proper position for welding. This was more work than actually making the bracket itself, and may not be necessary, but it worked well for me. The welding fixture was made from two short pieces of 2" tubing held in position with some scrap aluminum I had in my shop.

All the materials are available from the Aircraft Spruce catalog and they will cut the pieces for you. For example, I ordered one foot each of the 2" and 21/8" exhaust pipe. The 2" was used for the welding fixture and the saddles were cut out of the 21/8" piece. I had them cut the 5/16" tubing into three 16" pieces. The flat plate was a minimum order, maybe 1/2 square foot. All the parts cost less than $30. The springs came from a local hardware store.

The parts were TIG welded by a friend, but other methods would work too.

I'm not sure about the legality of this bracket, but in my case the A&P/IA called it a "repair." Since he had welded the original several times, he was aware of the problem and thought the new bracket was a big improvement.

The clamps are stainless worm-drive hose clamps, and the pin that keeps the pipes from sliding under the clamp is a steel rivet with the head filed flat.

Still Chase

Santa Barbara, CA